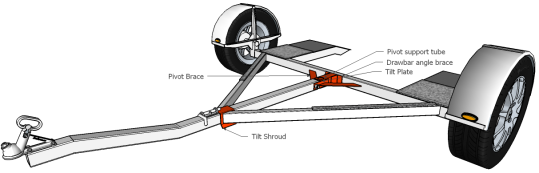

Tow Dolly

Tongue & Sub Chassis Components

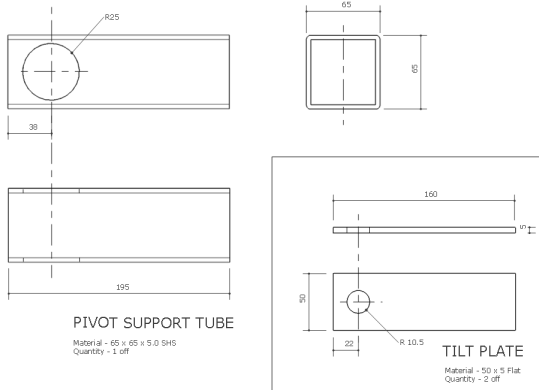

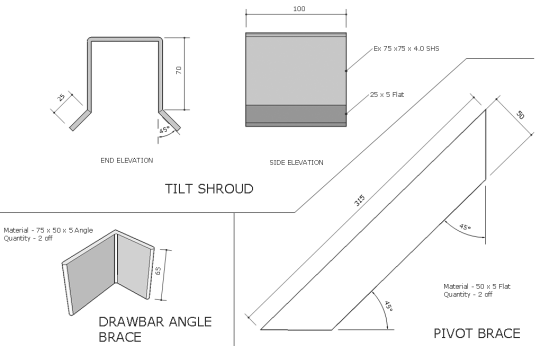

Fabricate the additional drawbar and tilt components as per the details below -

The pivot support tube hole for mounting the pivot shaft, requires a relative amount of accuracy to ensure a snug fit for the shaft as well as being square to the upper surface of the tube.

Use a 50mm bi-metal holesaw suitable for cutting steel if available - if not, use a 51mm holesaw (2"). Pre drill a small centre hole on both sides of the pivot support and clamp the RHS to the drill press bed.

Use a slow cutting speed and plenty of cutting fluid to keep the holesaw cool and lubricated.

Fabricate the tilt shroud from a section of 75 x 75 x 4.0 SHS by cutting off one face (remove the face with the internal seam weld) and welding flatbar as shown above.