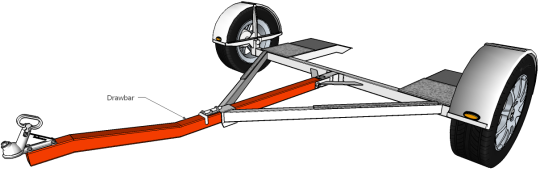

Tow Dolly

Tongue

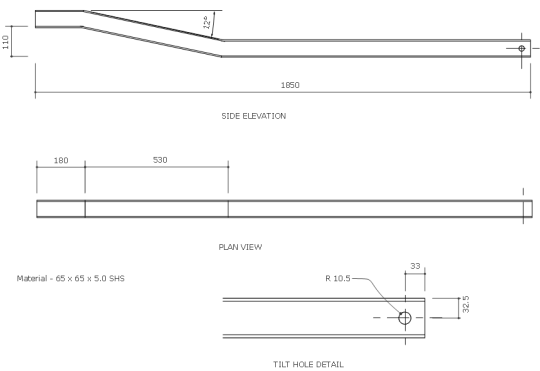

If you do not have access to the correct equipment, it is preferable to get the drawbar professionally bent/rolled to ensure the integrity and strength of the hollow section is not compromised.

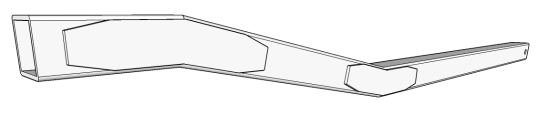

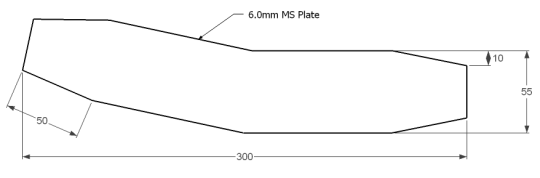

It is not recommended to cut and weld the drawbar to get the desired shape, but if there is no other option, strengthening side plates need to be fitted. See below for more details.

The side plates need to be fitted to both sides of the drawbar and stitch welded evenly around the plate. Stagger your welding to prevent any twisting or distortion of the drawbar from excessive weld heat.

Mark out and drill the tilt hole. Ideally drill from both sides if you do not have access to a drill press to prevent any offset of the hole.

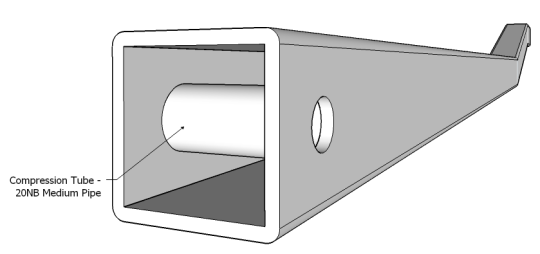

Fit and weld a compression tube within the drawbar for additional strength. The compression tube is only required to be securely welded - a full weld is not required.

Pre drill the drawbar for the coupling as per the manufacturers recommendations.

Australian Trailer Builders -

Now is a good time to fit the safety chain to the trailer - the safety chain must be permanently attached to the trailer (welded) and the weld must extend around 50% of the circumference of the welded link and the adjoining link must have free movement.

Weld the safety chain as near as practicable to the coupling. If fitting 2 chains, they must be mounted either side of the centreline of the drawbar.

Click here for more details on Australian Safety Chain & Shackle Regulations