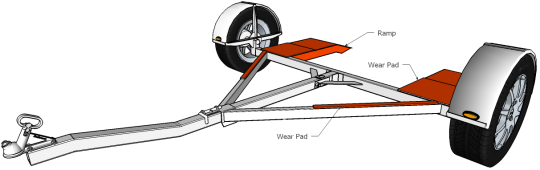

Tow Dolly

Ramps & Wear Pads

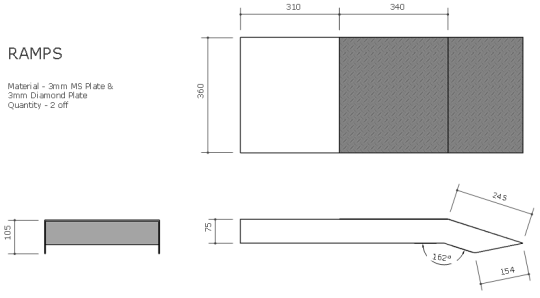

The ramp is required to be fabricated from plain 3mm steel plate to allow the load bearing wear pad to locate. Steel or alloy diamond plate can be overlayed outside of the wear pad area.

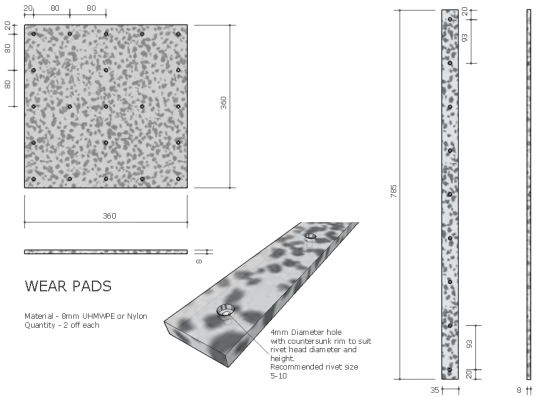

Wear Pads

The wear pads are designed to give a good load bearing surface allowing the top tow dolly deck to rotate smoothly and with correct mounting and regular maintenance, should give many years of service.

Note - A drill press should be used for drilling UHMWPE (Ultra high molecular weight polyethylene) or Nylon. The wear pad must be clamped to the drill press bed prior to drilling and a depth limiter used for the countersunk hole. Be careful not to deform the material when clamping, use only enough pressure to prevent movement.

Step drilling is also recommended - start drilling with a small diameter drill working up to the finished diameter.

UHMWPE and Nylon have a tendency to grab onto the drill bit and pull the drill through making the hole unusable.

Once the sub chassis has been welded together, predrill the sub chassis to match the wear pad holes. 5-10 aluminium or steel rivets are recommended for fastening to the sub chassis.

Note - Do not to fasten the wear pads to the sub chassis at this stage - install only when the trailer has been fully fabricated, welded and painted/galvanised.