Tow Dolly

Pivot Assembly

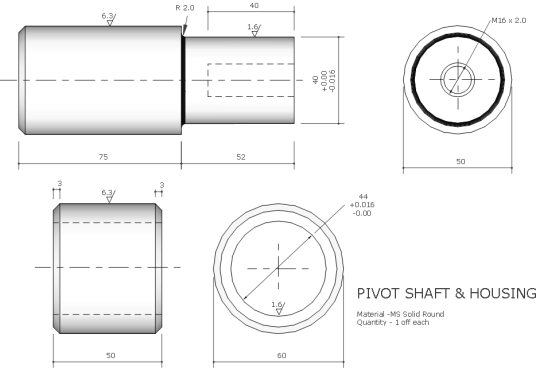

Unless you have access to a lathe, get your local machine shop to machine the pivot shaft, housing and pivot cap as per the dimensions below.

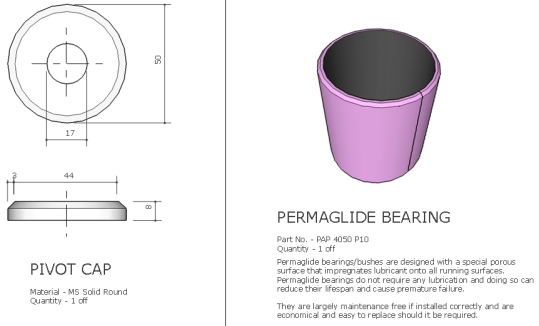

The permaglide bearing is available from most good bearing suppliers and are relatively well priced. They have the advantage of never requiring lubrication and if installed correctly are pretty much "fit and forget".

The inside of the bearing has a specially coated porous surface that when in contact with the shaft, transfers and impregnates the inbuilt lubrication onto all running surfaces.

Note - Do not, under any circumstances, if using the bearing recommended here, lubricate the bearing or shaft with any oil or grease, silicon or other type of lubricant. Doing so can reduce the bearings lifespan and cause premature failure of the bearing.

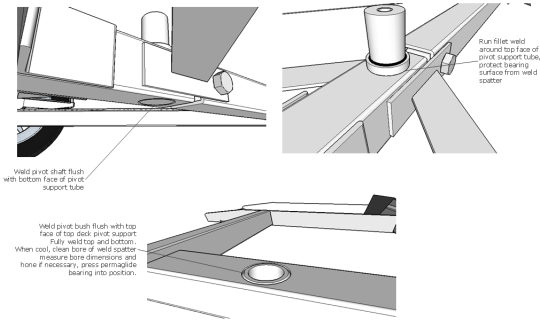

Before welding the shaft and housing/bush into position, temporarily fit the main wear pads to the sub chassis and permaglide bearing to the bush. Position the shaft within the pivot support tube and bush in the top deck support (put a small tack weld to keep in place) as per the details below.

Position the top deck on the sub chassis and align and clamp together.

When happy with the position and alignment, tack weld both the bush and shaft securely.

Remove the top deck and carefully remove the permaglide bearing.

Remove the wear pads from the sub chassis and wrap some non flammable tape or leather offcuts around the bearing surface of the shaft. Run a good hot weld around the top face of the pivot support tube making sure that there is good penetration into the shaft.

To prevent heat distortion and shrinkage to the bush, evenly pre heat the bush with an oxy/propane or oxy/acetylene torch prior to welding.

Once the bush has been heated, run a good hot weld bead around both sides of the bush, again making sure that the majority of the weld heat is put onto the bush to ensure good penetration.

Once welded, let the components cool down slowly, do not quench or spray with water. The crystalline structure of the steel can be adversely affected by rapid cooling leading to potential weakening of the pivot.

Before fitting the premaglide bearing back into the bush, clean the bore of any weld spatter. Measure the bore dimensions and hone out if necessary.