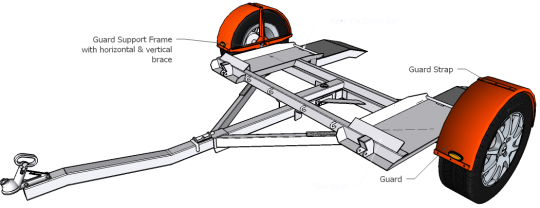

Tow Dolly

Fender Assembly

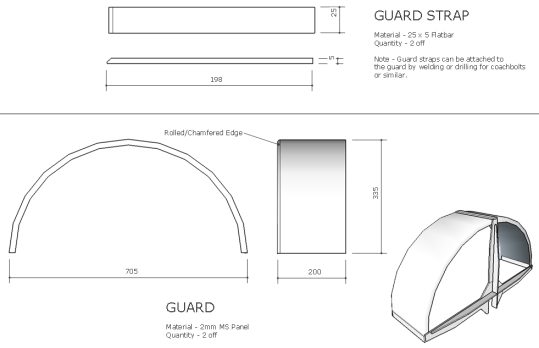

Setting up the guards is best done with the hubs and wheels fitted to the sub chassis. Because the trailer has no suspension to allow for, the clearance between the tyre and the guard can be kept to a minimum.

The only requirement is that there is enough clearance for the lighting cables to run behind the guard with sufficient clearance to prevent contact between the tyre and cable and to allow small rocks and stones to pass between the tyre and guard without jamming and potentially damaging both tyre or guard. I would recommend between 30 and 40mm clearance.

The width of the guard needs to be as close to the tyre width as possible to prevent interference with the towed vehicle when the top deck has fully pivoted. The inside edge of the guard should be flush with the tyre sidewall.

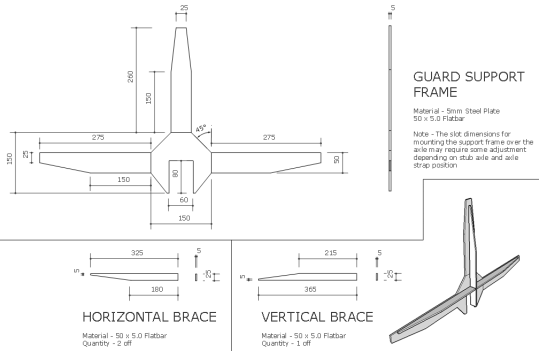

The guard support frame needs to be as strong as practical to prevent the guard from wobbling and deforming during normal use, as well as giving it strength from knocks and bumps.

The guard can be welded to the guard straps, but as the guard is the most prone to getting damaged, it is recommended that the guard is bolted on for quick repair or replacement.

Some modifications to the guard support frame and both the horizontal and vertical brace may be required to fit correctly over the axle and to give even clearance between the tyre and guard.