4'6" X 7' SINGLE AXLE TRAILER: CHASSIS TRIMS

This section covers the all important tongue angle gussets which provide additional strength and prevents metal fatigue when the tongue flexes. Also covered is the coupler mount, conduit for supporting the lighting cables and fitting a deck joiner.

TONGUE ANGLE GUSSETS

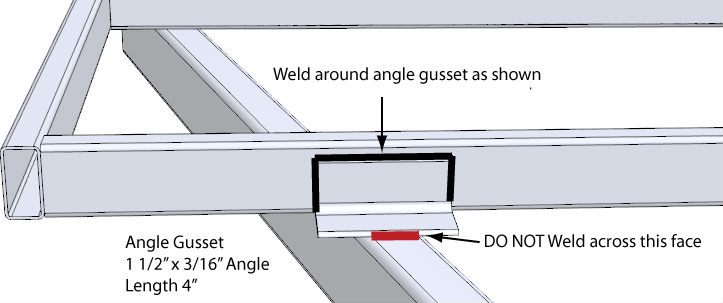

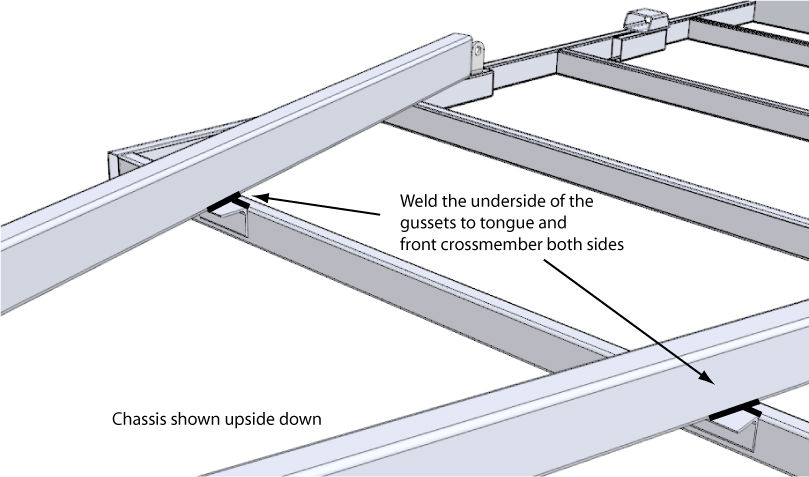

Where the tongue meets the front crossmember, fit a piece of 1 1/2" x 3/16" equal angle approximately 4" long over the exposed section and weld around the angle on the crossmember (Never weld across the top of the tongue) and a couple of welds under the angle gusset where the top edge of the tongue meets. Round off the outside edges to prevent any injury to your shins.

The angle gusset will give the tongue and chassis a stronger and stiffer structure at this point.

TOPSIDE

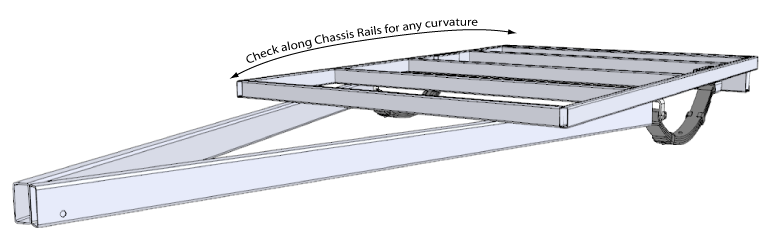

Double check all the welds on the tongue and chassis and grind/buff any sharp burrs and edges before flipping the trailer right way up.

Sit the chassis on your stands or trestles and run an eye along the length of the chassis frame and check that the frame is level and straight. Any extreme twisting of the frame will need to be heat shrinked to correct before continuing. Twisting or bending of the frame normally occurs when there has been too much heat applied through welding on a poorly clamped chassis.

To correct any major twisting, weld up the top of the chassis where the welds are missing (don't weld along the front chassis crossmember and tongue), recheck any twisting and mark where the centre of any bending is occurring. Using a oxy/acetylene/propane torch heat the side that needs to be shrunk and once nice cherry red, quench quickly with cold water. This will cause the steel to change structure and shrink hopefully correcting the problem.

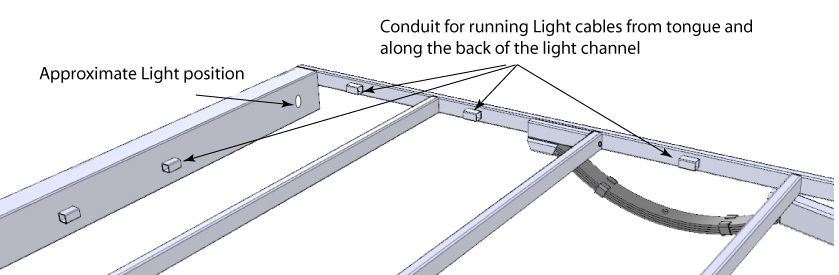

LIGHTING CONDUIT

Once all the welds have been laid, cut short sections of pipe(1/2"NB or similar) or small box section (1" x 1") around 1 1/2" long and run these down one side of one of the chassis rails at regular intervals of around 10-12" apart from the inside end of the tongue back, and also along the back of the light channel. These pieces of pipe will be your conduit for running your lighting cable along the trailer and will support and protect the cable.

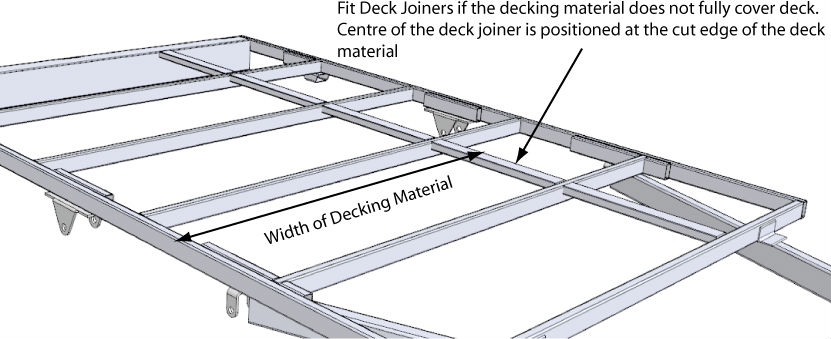

DECK JOINER

If you are using sheet decking like plywood or alloy/steel sheets, you may need to run a deck joiner down the length of the chassis. This is to support both edges of the sheets if the sheet is narrower than the width of the required deck. For example, if you have a 4'6" wide deck and your sheets of plywood are only 4' wide, you will need to have support under the sheet between the cross members for both the 4' wide sheet and the 6" wide sheet.

Deck joiner allows joining of panel decking where the width is greater than the panel.

Deck joiners can be offcuts of 2" x 1" RHS laid between the cross members with the widest section facing up to a length of folded panel steel in a 'U' section notched and welded along the length of the trailer making sure that the center of the deck joiner is where the cut edge of the sheet will be.

Next we will build and fit the sides - Click SIDES below