4'6" X 7' SINGLE AXLE TRAILER: AXLE

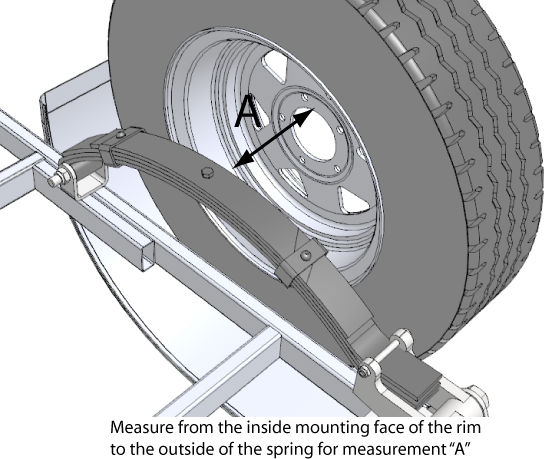

Before measuring up our axle, fit the springs back onto the chassis.

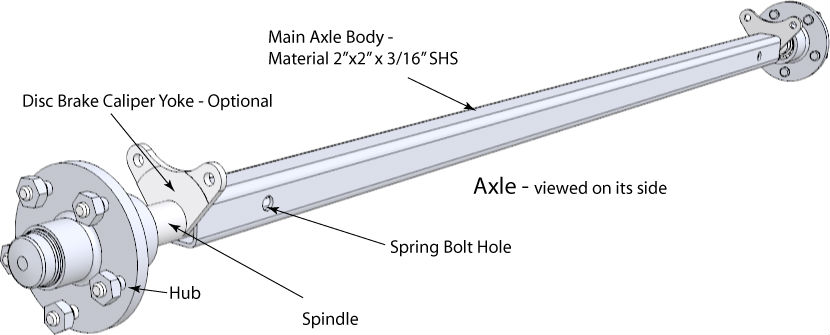

Getting the required axle measurements to your axle manufacturer as soon as possible will reduce the waiting time while your axle is being fabricated or otherwise check out here to build your own.

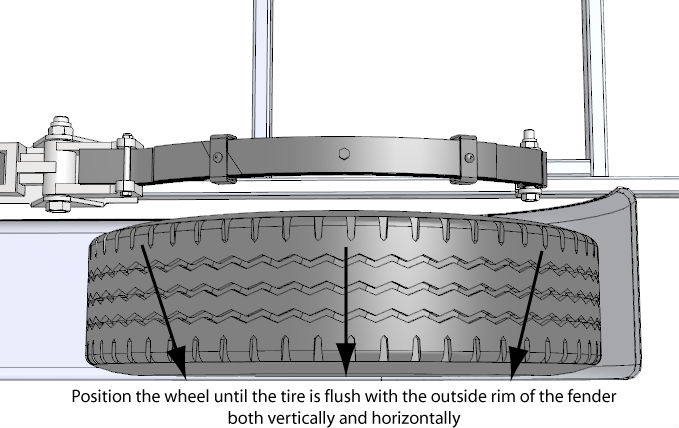

Firstly we need to clamp the fender approximately around the area where it is to go. If you are unable to clamp the fender or if the clamps will not hold, tack weld the fender on.

Position your tire and rim inside the fender and line up the outside of the tire flush with the rim of the fender, both vertically and horizontally. If you are pushed for room within the fender, you can move the tire out so that the start edge of the tire tread is flush with the fender.

Once the tire is in position, measure from the inside hub mounting surface of the rim, to the outside edge of the spring. If your springs are set up correctly this will be the same measurement as the outside edge of the chassis. We'll call this measurement "A".

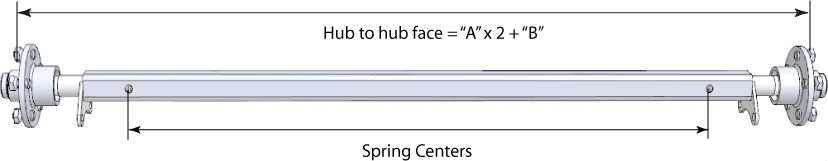

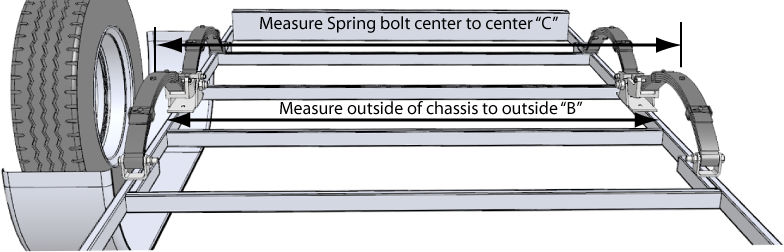

Measure your chassis width across the central part of your chassis for measurement "B". The Hub to Hub face measurements will be measurement "A" x2 (doubled) added to measurement "B".

Measuring between the spring center bolt centers will give you the spring centers. Another way to get this is to measure your chassis width "B" and subtract the width of one spring.

These measurements should be all that is needed to get the axle manufacturer started. If you are going for a different style axle (ie, stepped or dropped axle) then further measurements will be required.