Positioning of the guard is ideally done with the axle and wheel fitted to the chassis, to accurately set the gap guard/tyre gap.

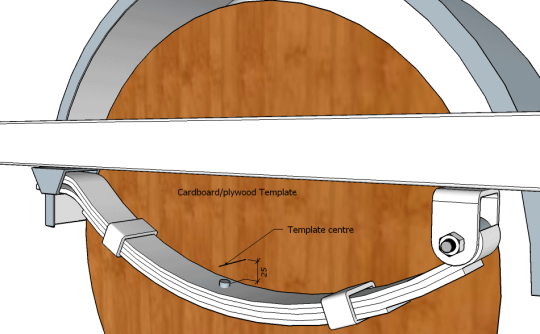

If, as in most circumstances, this is not possible, cut a cardboard or plywood template the same overall diameter of the tyre, mark the centre and clamp the template to the chassis rail with the template centre, 25mm (for 50 x 50 SHS axle) above the centre of the spring bolt.

Ideally align the template centre with the corresponding angle the spring bolt is lying on.

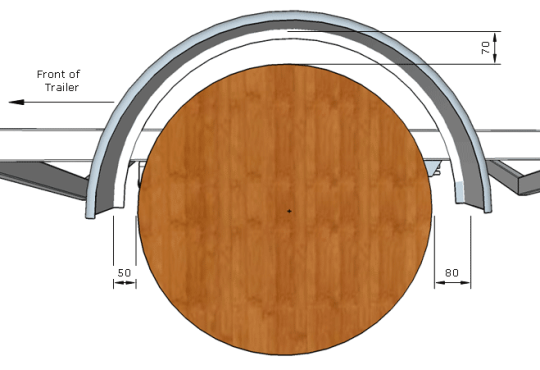

Position the guard against the chassis rail allowing a 50mm gap between the template and the front edge of the guard. From the top of the template to the guard should be around 70mm and approximately 80mm at the rear, Dimensions may differ if template/tyre size differs from the model shown (600mm diameter - 165R13C)

The extra clearance at the top and rear of the guard allow for movement of the suspension/tyre during normal operation. Tack weld the guard in position and double check clearances.

Position the guard so that the apex of the guard is sitting 210mm from the top of the chassis rail. Adjust the front edge of the guard so that it is aligned with the 370mm mark and clamp the guard in position.

Double check that the guard is in the correct position and tack weld.

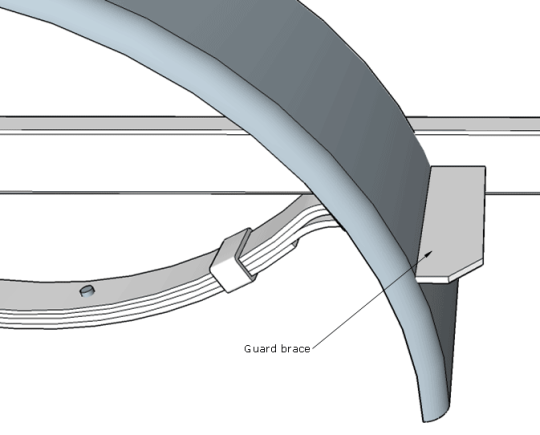

GUARD BRACING

Fit guard braces to both sides of the guard, positioning them along the centre line of the chassis rails.

Before tacking the braces in position, check that the guard and braces are square to the chassis. Once square, tack weld braces to the guard and chassis.

Double check position and squareness of the guards and braces and fully weld.