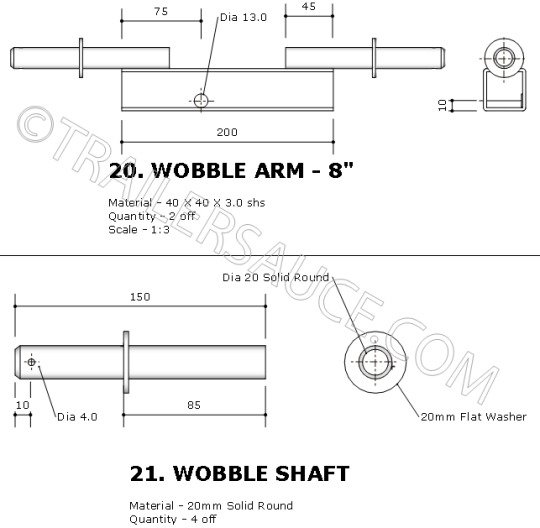

Correct welding of the wobble shaft onto the arm is required to ensure good strength.

Due to the larger mass of the wobble shaft, a hot weld is required to give good penetration into the shaft, taking care not to blow through the thinner wall of the SHS.

Insufficient weld penetration of the wobble shaft/arm may cause the wobble unit to fail in service.

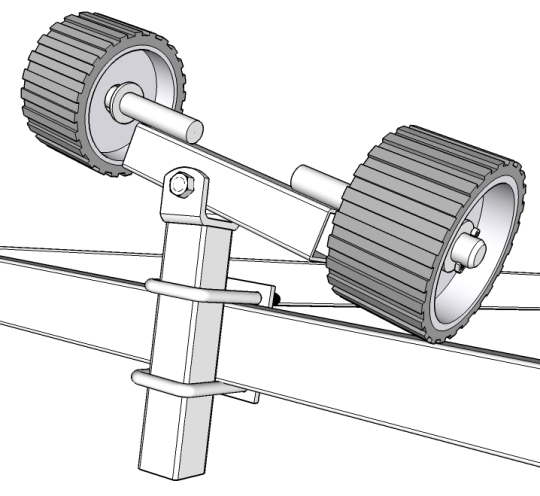

The wobble rollers shown in this plan are 130mm diameter "Grey Barrons" with a 26mm diameter bore available from most trailer parts suppliers.

Changes may have to made to the overall shaft length between the washer and split pin hole with different wobble rollers.

Double check the internal dimensions of your rollers before fabricating.