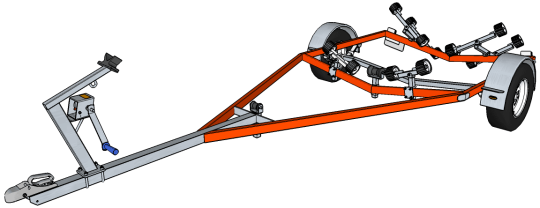

4.7m (15ft) Boat Trailer

Chassis Frame

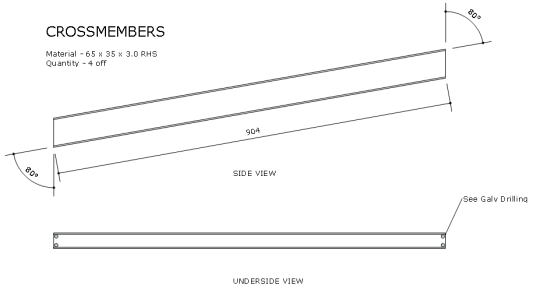

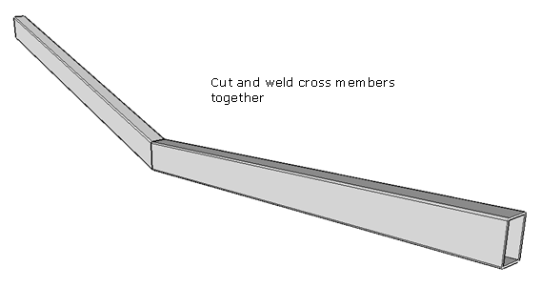

Firstly, cut the 4 cross member sections and weld together.

Drilling the galvanising drain holes can be done now, but best left until the chassis is fully welded.

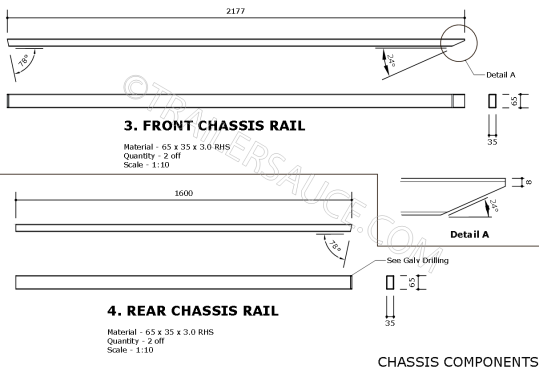

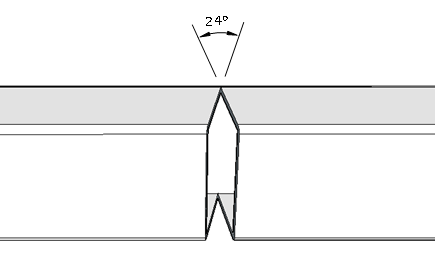

The chassis runner can be fabricated by either cutting 2 sections and welding together as per the plan below, or by notching out a vee section and bending the chassis runner to close up the notch gap and welding.

Notching is the preferred method, but accuracy and tidy cutting of the notch is required.

Closing up the notch gap should only be done once, opening and closing of the gap will cause rapid metal fatigue where the steel is bent.

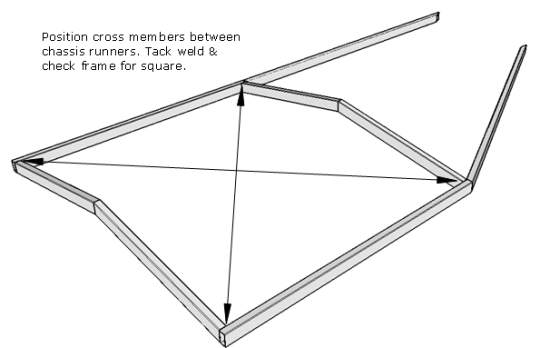

Tack weld the chassis runners or the bent notched sections and lay on a flat surface with enough room to fit the cross members between.

Square the chassis frame by measuring diagonally across the frame at identical points. Adjust the frame until both measurements are identical. Sandbag or clamp the frame securely and put some good tack welds into the frame.