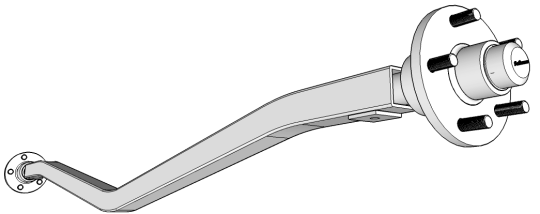

Gull wing axles should always be formed from one piece of hollow section steel to provide the best overall axle strength and reduce the amount of fatigue and stress points that cutting and welding can incur.

Unless you have access to pipe/tube forming equipment and know how to use it correctly, building a gull wing axle for your boat trailer should be left to the professionals.

It is best to measure and order an axle as soon as possible to reduce any delays getting the trailer on the road once complete.

MEASURING THE AXLE

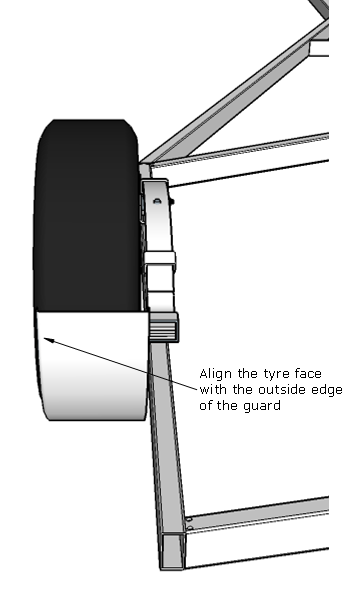

Firstly we need to clamp the guard approximately around the area where it is to go. If you are unable to clamp the guard or if the clamps will not hold, temporarily tack weld the guard in position.

Position the tyre and rim inside the guard and align the outside of the tyre flush with the rim of the guard, both vertically and horizontally.

If you are pushed for room within the guard, you can move the tyre out so that the edge of the tyre tread is flush with the guard edge.

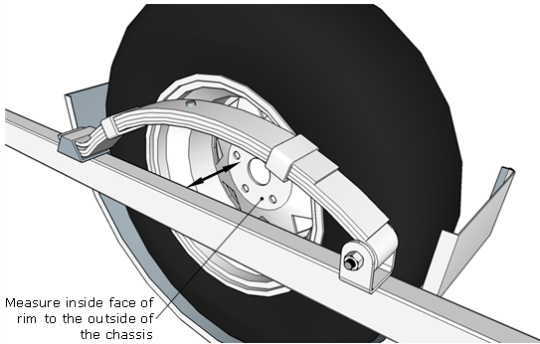

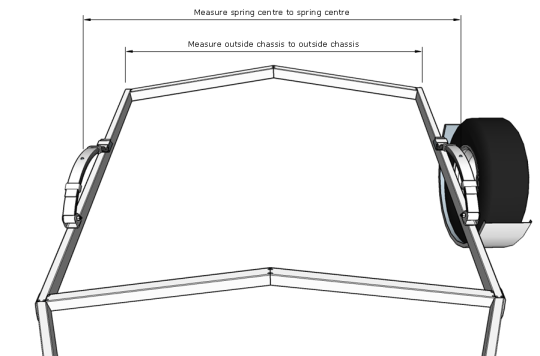

Once the tyre is in position, measure from the inside hub mounting surface of the rim to the outside face of the chassis for measurement "A". If the springs are set up correctly and you are unable to get a good measurement to the chassis, you can measure to the outside face of the spring. This will be the same measurement as the outside edge of the chassis.

Measure your chassis width across the central part of your chassis for measurement "B". The Hub to Hub face measurements will be measurement "A" x2 (doubled) added to measurement "B".

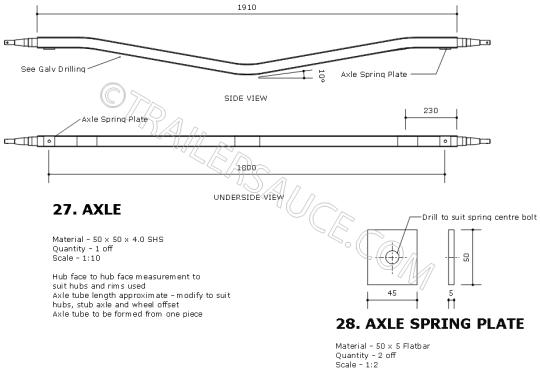

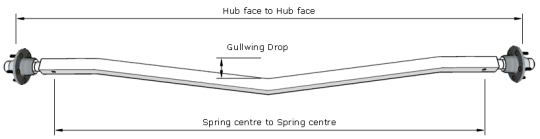

Your axle supplier will require both the hub face to hub face and spring centre measurement. They may also require a measurement for the gullwing drop - For this trailer the gullwing drop should be 100mm.

The drawing below is representative of the axle measurements, but differences in hub and stub profiles, rim offsets and guard widths need to be checked with the actual equipment being used on the trailer and measurements adjusted accordingly.