3.6 X 2.0m Flatdeck Trailer

Trailer Trims

There are always the last little bits that need to be added on to make finishing the trailer that much easier.

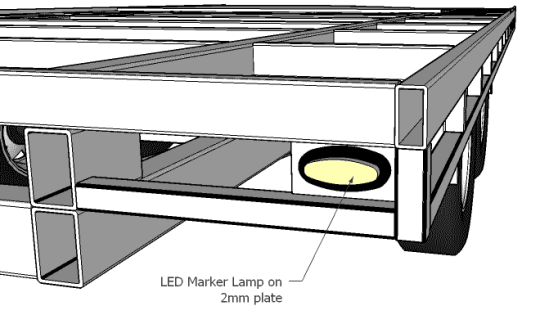

FRONT MARKER LIGHT MOUNTS

Cut a couple of marker light plates to suit the size of your proposed marker lights.

2mm plate is suitable and predrilling for both screws and cable is recommended before fitting.

Weld the plate to the back side of the front tie rail and cross member to give maximum protection to the light.

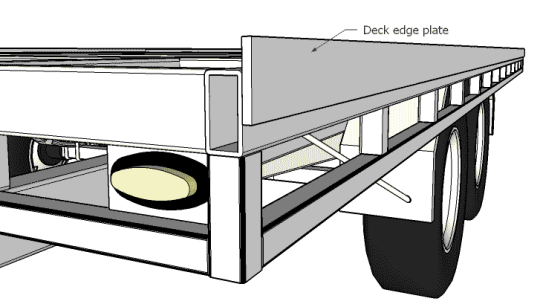

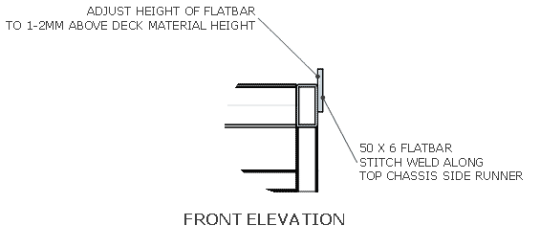

DECK EDGE PLATE

The deck edge plate gives protection to the decking material, particularly if the trailer is to be side loaded with fork hoists or tractors. It also gives a good base for welding hinges, if you are fitting sides to the trailer.

The deck edge plate is ideally positioned 1-2mm higher than the proposed decking and is stitch welded along the full length of the trailer.

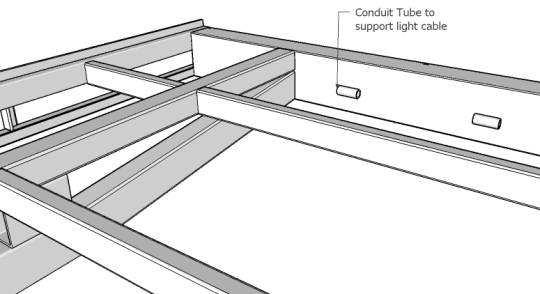

CONDUITS

To help support the cable along the back side of the light channel, weld, at regular spacing, 3 or 4 tubes (1/2" pipe or 25 x 25 SHS or similar).

Before welding to the trailer, remove all burrs and sharp edges.

Prior to fitting the cable, glue in a split section of plastic gardening hose with silicon sealant or similar to prevent any chafing of the cable against the steelwork