3.6 X 2.0m Flatdeck Trailer

Guards

FABRICATING & FITTING GUARDS

Get a couple of your mates around for a quick beer and to help you flip the trailer over right way up. Beware that the chassis will be very heavy and unbalanced, and there are plenty of sharp edges to catch yourself on.

Once flipped over, set the chassis up on some sturdy trestles or axle stands to allow you to finish welding the top of the chassis and fit the suspension and axles.

Fit the wheels and tighten all nuts and bolts on both suspension and wheel hubs.

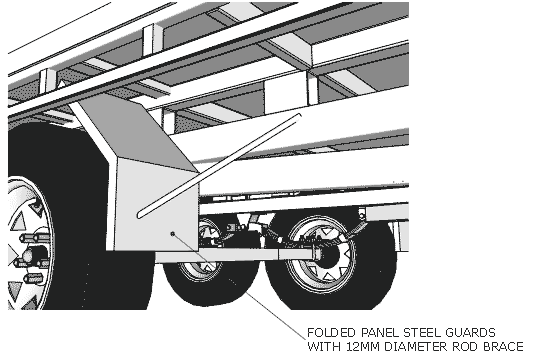

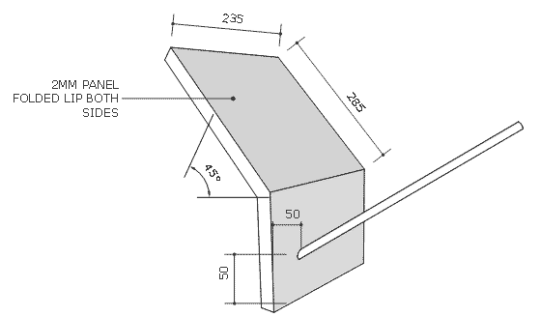

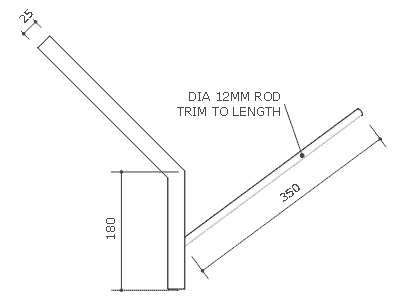

Fold up 4 guards as per the diagram below using 2mm panel, notch out the lips where the guard bends, fold, and weld together at 45 degrees.

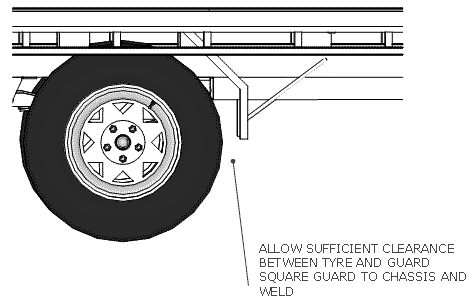

Position the guard so that there is good clearance around the tyre - 75mm is a good guideline.

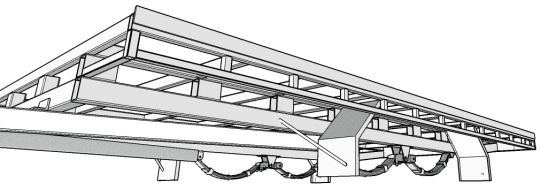

It is an advantage if you are able to get the top edge of the guard to contact a cross member.

If this is not possible, cut and weld a couple of tabs to secure the top of the guard to the nearest cross member.

Clamp the guard in place, check your measurements, stand back and eyeball the guard both from the side and front/back to make sure all looks good and square.

Tack weld in position.

Mark the guard where the bracing rod will sit. Trim the rod brace to fit. Once happy with the brace and its angle, cut the other 3 to match.

Tack weld the brace in position and take a couple of measurements of its position on the chassis so you can weld the other guard braces in the same position.