3.6 X 2.0m Flatdeck Trailer

Drawbar Components

This section covers the all important drawbar angle gussets which provide additional strength to the drawbar as well as preventing metal fatigue as the drawbar does its work.

With the flatdeck trailer there are a couple of coupling mounting options and these are detailed below.

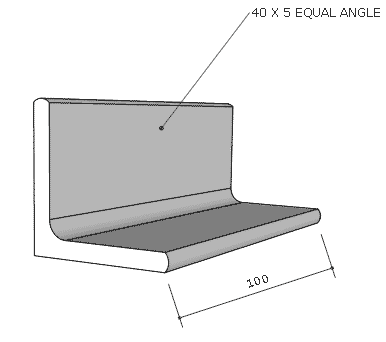

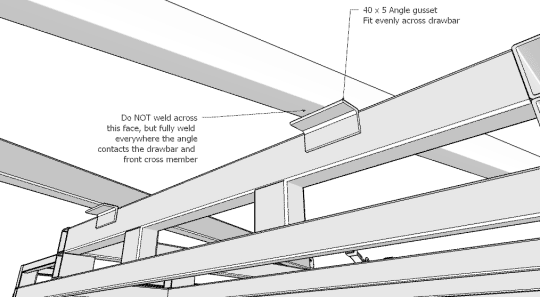

DRAWBAR ANGLES

Where the drawbar meets the front crossmember, fit a piece of angle 40 x 5mm approximately 100mm long over the exposed section and weld around the angle on the crossmember (Never weld across the top of the drawbar) and a couple of welds under the angle where the top edge of the drawbar meets.

Round off the outside edges to prevent any injury to your shins.

The angle will give the drawbar and chassis a stronger and stiffer structure at this point

COUPLING MOUNT

There are a couple of methods of mounting the coupling to the drawbar, and due to the way the trailer is built, the coupling base needs to be level to the base of the drawbar to accommodate a standard towing height of 450mm.

The mounting method is determined by the type of braking the trailer is to have - hydraulic surge or electric.

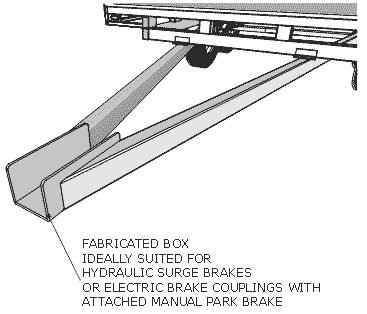

The fabricated box is ideally suited for hydraulic surge braking or electric brake couplings with an attached manual park brake lever.

It gives reasonable protection from knocks to the hydraulic master cylinder, but does take a bit of effort to line up and fit to the drawbar.

The coupling box can be either folded or fabricated from 3 plates.

Accurate alignment of the box within the drawbar is critical and time should be taken to check and double check measurements prior to cutting the drawbar.

Click here for more details on the coupling box.

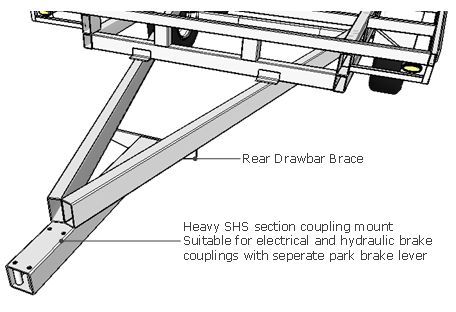

The second, more commonly used option is fitting a section of 90 x 90 x 5.0 SHS under the drawbar, and mounting the coupling on top.

This setup is suitable for both unbraked and hydraulic braked couplings, as well as electric couplings with a separate park brake lever.

This style coupling mount is very quick and easy to build and fit, but care does need to be given to good quality welding (as you should do with all the welding on the trailer).

Compression tubes need to be fitted within the cavity of the coupling mount to prevent the deformation of the SHS when the coupling bolts are tightened. A rear drawbar brace gives added strength.

Blanking off the open ends of the drawbar make for a nicer looking trailer.

Click here for details of the RHS coupling mount

Australian Trailer Builders -

Now is a good time to fit the safety chains to the trailer - the safety chains must be permanently attached to the trailer (welded) and the weld must extend around 50% of the circumference of the welded links and the adjoining links must have free movement.

Weld the safety chains as near as practicable to the coupling - they must be mounted one on either side of the centreline of the drawbar.

Click here for more details on Australian Safety Chain & Shackle Regulations