Trailer Tongue Design & Function

Perhaps the most important and overlooked part of the trailer design is its tongue. Have a look at a couple of trailers around your area, and you will see a multitude of materials and designs.

The tongue does a couple of important jobs apart from being the part that keeps your trailer attached and at a distance from your tow vehicle. The tongue keeps your trailer in balance when towing and assists in keep weight on the tow hitch which is required for controlled towing. It also adds stiffness to the chassis and depending on the axle and load placement will assist in keeping the trailer running true and stable.

A tongue needs to have good vertical and sideways strength and depending on the size of your trailer and the loads you wish to carry, this will determine the size of the material required and the design that you should use.

The tongue does a lot of work while towing. Every little bump in the road and every turn you make transfers stress through the tongue and compresses, twists and stretches the tongue material constantly. If the trailer has been built with an undersized tongue or the trailer is constantly overloaded or unbalanced, this repeated loading and unloading (cycling) of stresses on the tongue can create microscopic cracks within the grain structure of the tongue material.

Over time a microscopic crack can grow and eventually reach a critical size, where the tongue may suddenly fracture and ultimately fail.

This can also occur on a tongue that has been damaged or distorted through normal use.

The amount of cycles that a tongue can take before failing is dependent on a couple of factors -

- The tongue design

- The tongue material size - bigger is always better to a point

- How the tongue is attached to the chassis

- tongue length

- How the trailer is loaded and towed

Tongue Design

There are 3 main styles of tongue -

- The straight tongue

- The Compound tongue

- And the “A” frame tongue

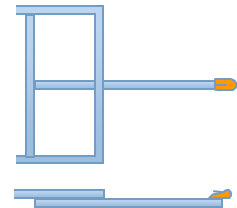

Straight Tongue

This design harks back to the old horse and cart where you had a horse tethered to either side of the tongue. It is a bit old fashioned but still has its uses particularly on dinghy and agricultural trailers.

Whilst this design has less chance of getting jackknifed when reversing, if the tongue does get damaged it creates a highly stressed section which can rapidly cause internal cracking or failure.

Because straight tongue are centrally mounted, they do tend to come under a lot of vertical stress particularly where the tongue and chassis meet. This stress increases if the load is incorrectly balanced over the axles.

Length should be kept to a minimum as the longer the tongue the less load is able to be carried and the weaker the tongue becomes.

The strongest design for a single tongue is to have 2x RHS (Rectangular Hollow Section) pieces laminated together (stitch welded) and fitted to the trailer with the longest edge vertical.

The tongue needs to go under the chassis a minimum of half its protruding length and attached to at least the first intermediate cross-member.

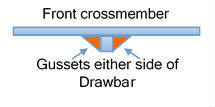

Triangular gussets, bracing the tongue to the chassis front and intermediate cross members should be fitted.

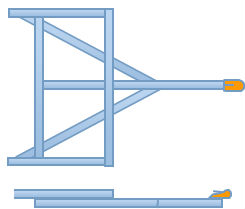

Composite Tongue

The composite tongue is a variation of the single tongue design with lateral supports to both strengthen the tongue and provide support to the chassis.

This style enables the tongue to be slightly longer as well as not so heavy a section of steel.

Composite tongues give the benefits of good clearance to the tow vehicle when reversing around sharply and give more support to the sides of the trailer.

You will find a lot of single tongue trailers retro fitted with the composite angle frame to stabilize and control the trailer better, as well as adding strength.

Ideally the composite angle frames should go under the chassis at least to the first cross member.

Boat trailers commonly use a compound tongue using the angle sections as part of the chassis frame.

The strength in this comes from the bow post which supports the front keel of the boat.

When the boat is locked into the bow post and secured to the trailer the boat effectively becomes part of the chassis/tongue.

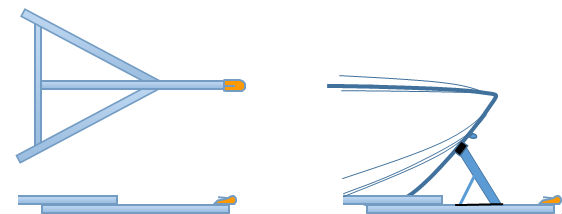

“A” Frame Tongue

This style tongue is one of the most common due to the strength the full angle frame gives to the trailer. It supports the outer edges of the trailer and prevents the chassis from twisting when poorly loaded.

The length of the tongue can be increased as long as the material section is increased in size or bracing (see below) is added to ensure tongue stiffness and rigidity.

The longer a tongue can be (to a point where the tongue weight becomes excessive) the more smoothly and stable the trailer will travel. It will also be more responsive and forgiving when reversing.

Short tongue trailers are prone to rapid and sometimes unexpected turning, slight movements of the towing vehicle can put the trailer into a jackknife in a moment of inattention.

Out of the three tongue designs, the “A” frame is structurally superior as it offers excellent horizontal stiffness and good vertical support. Any stress’s on the tongue are transferred to the chassis outer edges through the tongue and effectively share the load.

One disadvantage is the greater chance of the tongue being damaged when jackknifed while reversing.

How your Coupler choice can affect your Trailer

The type of coupler you choose for your trailer can affect the overall strength of the trailer tongue and chassis. If your axle(s) is well set back from the center of the trailer you can get away with having a shorter tongue length (from the front of the chassis to the coupler). There is a rule of thumb to have the axle set at 60% of the chassis length, and this is fine for a lot of situations especially where a ramp is fitted, but if not, I prefer to have the axle set at 3" to 4" (75-100mm) behind the centre of the chassis and have a nice length of tongue sticking out the front.

The reason for this preference, it that the longer tongue gives more stability to the trailer, when reversing you can see more of the trailer and gives the trailer more room to mount tool boxes, spare wheels, bicycle racks and the like. Having the axle set just slightly back from the center allows the trailer load to be more efficiently balanced without adding too much additional weight to the tongue.

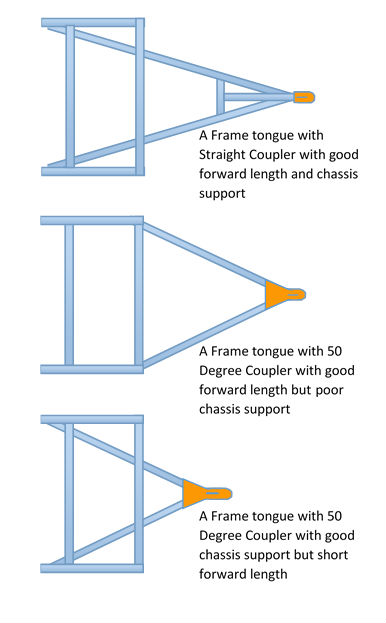

Fitting a straight coupler to an A frame tongue, does take a bit more work inserting a straight steel section within the A frame, but if you are considering fitting hydraulic brakes to the trailer at a later stage, then this is an easy retro fit if the straight insert is fitted.

Ideally the tongue should finish at or near the front spring hanger to give the chassis additional strength. Terminating the tongue too close to the front of the trailer allows the chassis to flex and twist and could compromise its stability and trailer lifespan.

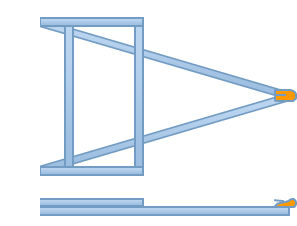

One of the drawbacks of an "A" frame coupler is the compromise you have to make regarding the length of the tongue forward of the chassis and the amount of support the tongue gives to the chassis. Depending on the width of the chassis, to ensure the tongue goes under the chassis sufficiently to give support, the forward tongue length is reduced. My personal preference is for straight couplers which can be mounted to the "A" frame tongue where the angle of the "A" frame can be adjusted to get best chassis support.

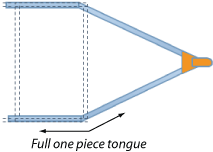

Wrapped Tongue

If you have to use an "A" frame coupler, and would like to have a reasonable length of tongue forward of the trailer body, it is recommended that you build the tongue to be wrapped along the side of the trailer. A wrapped tongue (some manufacturers call them a "fully wrapped tongue") is where the tongue material is mitered at the point the A frame intersects with the chassis and bent to follow the line of the chassis back to the front spring hanger.

This stiffens the chassis considerably and will lengthen the life of both the trailer and tongue. The mitered section should be gusseted on the inside face and the wrapped section, stitch welded to the chassis rail long its length.

Tongue Length

Tongue length is the distance measured from the center of the trailer front cross member to the center of the tow ball and can be determined from a number of considerations. As well as having the choice of straight, composite, and “A” frame tongue, there are also the options of having a fixed length, extend-able, and tilting tongue. Each of these is discussed below.

Fixed length tongues are the most common and account for probably 95% of all trailers built. Most trailer manufacturers have their own standard length for a given size of trailer based on experience, trailer stability, turning and reversing responsiveness, axle position and the trailers maximum load capacity.

Fixed Tongues

Too short a tongue, and you run the risk of clipping the front of the trailer with your tow vehicle when turning corners and whilst the trailer will follow the tow vehicle nicely, when reversing, the trailer will be oversensitive. Short tongue trailers are prone to rapid and sometimes unexpected turning. Slight movements of the tow vehicle can put the trailer into a jackknife in a moment of inattention.

Short tongues are the domain of farm trailers and serious off road trailers due to their better tracking when taking tight corners (less chance of the trailer hitting fence/gate posts or trees when turning) and reduces the occurrence of the tongue bottoming out when going over and through steep undulating ground or sand dunes.

Trailer tongues need to be at least as long as half the tow vehicles width. Most cars and SUVs’ range between 5' to 6 1/2' (1500 - 2000mm) so the minimum length of tongue needs to be half of this plus a little bit more (say 8-12") (200-300mm) to gain a margin of clearance when turning and to add stability to the trailer.

Standard tongue lengths range between 4' to 6' (1200-1800mm) depending on the tow vehicle, what is going to be mounted on the tongue (toolboxes, spare wheel, bicycle rack, etc..), length of the load when carting over length goods (timber, pipes, kayaks/canoes and similarly long items) and the position of the axles in regard to the chassis.

For general cartage on a standard trailer with nothing mounted on the tongue apart from maybe a spare wheel and axle(s) mounted rear of the deck center, I would recommend a tongue length of 4' to 4'8" (1200 - 1400mm).This is a good compromise on length for stable towing and turning circle without adding unnecessary weight to the trailer.

If a full width toolbox or similarly wide items (bicycles, lawnmower deck, stone guard, etc) are to be mounted on the tongue, the tongue needs to be measured forward of these items to ensure sufficient turning clearance.

Another thing to be aware of is if you have a side hinged or top hinged rear door on your tow vehicle. Make sure that the door can open without hitting the front of the trailer or any accessories permanently fitted to the trailer.

Tongues over 5' (1500mm) depending on the material used, should be braced to give additional stiffness and prevent vertical flexing. See below for information on tongue bracing.

See also "Extendable Tongues", "Tilting Tongues" & "Tongue Bracing/Strengthening"