Coated Plywood Trailer Decking

Coated Plywood Trailer Decking

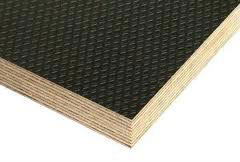

Coated plywood is also called Trans ply or Form ply. Predominately used in the truck decking industry, phenolic coated plywood is gaining popularity with the light trailer industry. Very thin veneers of birch or larch (0.0551" thick) are laminated together to form a very dense and structurally stable ply.

The top face has a thick layer of phenolic coating which gives the plywood a very hard, impact, abrasion and wear resistant surface. This layer has a mesh or diamond plate pattern pressed into the deck to enhance grip and friction for both man and load. The bottom face has a smooth finish which helps prevents moisture and road grime from settling. Coated plywood comes in a small range of colors with brown and green being the most common.

Because of the thinness of the veneers, the resulting boards are structurally stable and have exceptional strength, hence thinner boards can be used where heavier and thicker boards would normally be utilized.

For example where a 3/4" plywood board would be standard on a trailer, a 1/2" phenolic coated ply could be used without compromising strength if looked after correctly.

Coated plywood is not treated and relies on its coating to give protection from moisture. Any cut or machined edge where the plywood has been modified to fit the trailer will need a least two coats of protective paint to prevent any moisture from getting in. Larch has relatively good resistance to moisture induced rot, but birch, which is more common in coated plywood, is more suited to interior applications due to its poor relationship with moisture. Nevertheless, birch works well in decking applications as long as any cut edges are sealed and any fastening holes are sealed in some way to prevent water from getting in.

Personally, I would squirt a good dose of silicon sealant down the drill holes before inserting the fastenings and top it off with a coat of color matched paint. Any gouges or any decent scratches in the top face should be given a quick touch up with paint to prevent any water getting into the interior of the ply. Phenolic coatings are reasonably UV resistant but the coating colors will fade under harsh sunlight.