TRAILER COUPLERS

A coupler is a mechanical device which is attached to the end of the trailer tongue by bolting or welding. The coupler head fits over and clamps onto the tow vehicle hitch ball and allows the trailer to pivot and follow the tow vehicle. Couplers are manufactured commonly from pressed steel but cast iron couplers are available for heavier applications.

There is a huge range of couplings available on the market and your local trailer supplier will carry most of the following couplings. Hitch balls range from 1 7/8" up to 2 5/16" with 2" being the most popular

The following couplings are the most commonly used and there are many other types available not listed. There is the choice of having a straight coupler which is bolted or welded onto a 2" & 3" wide straight tongue or the delta shaped "A" frame coupler which is mounted onto an "A" frame tongue (50 degree angle). Both these couplers are suitable for use with electric drum brake trailers.

Coupler choice can affect the design of your trailer, check out "How coupler choice can affect your trailer" below. See also "Tongue Design" for additional information.

Straight Tongue Couplers

This is the most basic and cheapest type of coupler you can buy and is one of the simplest to operate and maintain. There are quite a few different models and styles available and can be bolt mounted or welded.

They are designed for light duty trailers with a straight or compound tongue and are good for trailers between 1000 lb - 6000 lb capacity.

They are available to suit a 1 7/8" & 2" tow hitch ball and can be bought to fit 2" or 3" steel section.

They operate with a trigger operated lever to close the coupler clamp under the hitch ball and a double action lock trigger/lever trigger to release the coupling. They should be regularly cleaned, lubricated and maintained as this type of coupling can be troublesome if the weather is very cold and wet, especially with cold hands.

The lever/clamp mechanism can seize up if sand or rust gets into the unit.

Straight couplers are available in galvanized, stainless steel, painted or zinc plated coatings.

A Frame Couplers

Another common type of coupler is the delta shaped A frame coupler which is easily attached to the trailer tongue by either bolting or welding.

The tongue is required to have an included angle of 50 degrees for the coupler to fit snugly.

The A frame coupler is suitable for trailers with a GTW (gross trailer weight) between 1000 & 15,000 lb depending on the model you purchase.

The clamping mechanism is similar to the straight coupler and requires good maintenance to ensure trouble free use.

The latch can be either lever/trigger style as per the straight coupler above or finger/thumb latch as shown on the A frame coupler.

A frame couplers are available in bare oiled steel, galvanized, painted or zinc plate coating.

Lever Type - Southern Hemisphere and Europe

This is the most common type of coupling on an unbraked trailer and is one of the simplest to operate and maintain. There are quite a few different models and styles available and have a multitude of mounting options. Some of the fancier models have a duo-fit tongue arrangement to allow fitting to 2 different diameter towballs.

The pressed steel coupling is one of the cheapest couplings available and is suitable for a towing capacity between 500- 900kg. They operate with a trigger operated lever to close the coupling tongue under the towball and a double action lock trigger/lever trigger to release the coupling. These are only suitable for lightweight trailers and should be regularly cleaned and maintained. This type of coupling can be troublesome if the weather is very cold and wet, especially with cold hands and can jam up if sand or rust gets into the mechanism. They are normally fixed to a straight drawbar with a couple of thru bolts and are easily replaced if required.

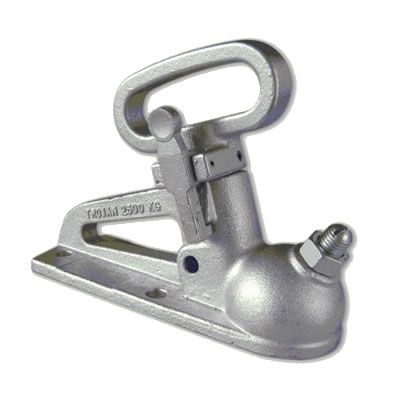

Standard Cast Lever Coupling

This coupling is the mainstay of the light trailer industry and is simple by design and function and almost foolproof in its use

It uses a cast iron enclosure which covers the towball and has a cast tongue which operated by the lever clamps the underside of the towball sphere and is kept in position by a loaded spring. A locking pin slides over the top of the lever to give additional safety protection by preventing the lever from lifting. The locking pin is turned ninety degrees to locate and lock itself.

Unless poorly lubricated, this coupling will give many years of use and the only maintenance required, apart from the odd squirt of grease is to replace the locking pin and spring as this is the most commonly damaged part of the coupling.

These couplings are rated between 2000 – 2500kg towing capacity and will have their rating cast into the body of the coupling.

Plunger Type Couplings

These couplings utilize a handle rather than a lever to fit and release the coupling and the main head casting is more formed to fit around the towball. The spring loaded tongue comes down at an angle behind the towball and prevents the coupling from lifting. On the side of the coupling a trigger style locking lever is provided to add extra safety. This type of coupling comes with a wear/anti-rattle adjuster on the front of the casting and can be adjusted to take up any slack within the coupling.

These couplings require regular lubrication to ensure continued ease of operation. The most commonly replaced part on this coupling is the the trigger lever, spring and pin and on older couplings the cotter pin between the tongue and handle can wear out and break. If the trailer has too much rearward weight and is lifting the drawbar up,(huge potential for an accident), the coupling can be nearly impossible to remove from the tow vehicle (you may need to get yourself and a couple of your mates to jump up and down on the drawbar to get the coupling to release). These couplings are rated between 2000 – 3500kg towing capacity depending on the braking systems used.

Hydraulic Brake Coupler (Surge Coupler)

Hydraulic brake or surge couplers are straight couplers with an in-built mechanically operated hydraulic pump (master cylinder) attached to a movable coupler head which provides hydraulic pressure to activate the trailer brakes.

The coupler uses the kinetic energy from the trailer moving towards the tow vehicle when the tow vehicle slows down or decelerates. The trailer pushes against the tow vehicle and the movable coupler head pushes backwards into the coupler body actuating a hydraulic piston(s) which pressurizes hydraulic fluid from a reservoir. The fluid under pressure is forced down the brake lines and activates the wheel brakes.

The amount of braking pressure applied to the brakes is proportional to the amount of braking applied to the tow vehicle and well maintained hydraulic brakes will give smooth and responsive braking.

There are plenty of variations on this design and some couplers will have spring and hydraulic dampening or one or the other to operate the master cylinder. Some units have adjustable head units which can be set up for differing ball sizes and most have an inbuilt breakaway brake lever and cable.

This style of coupler is suitable for trailers with a gross trailer weight (GTW) between 6000 lbs to 20,000 lbs. Double check the manufacturers rating to match your specifications and be sure to get the correct coupler for the weight you will be towing. A coupler rated at 12,000 lb will have limited braking capacity on a load of say 4000 lb. The reason for this is that the damper control in the coupler is set to operate within a specific weight range, for example - the 12,000 lb trailer will apply a lot more force on the coupler to activate the brakes, the lighter trailer will not have anywhere near the same forward momentum and the brakes may not even apply.

The majority of couplers are designed to be bolted to a 3" tongue and welding is not recommended or advised. If you require a weldable surge coupler, they are available at most suppliers.

Check with the manufacturers maintenance recommendations and follow them to the letter. Brakes need to work when you least expect it, poorly maintained brakes can result in a serious accident.

Reversing with a Hydraulic Surge Coupler

When reversing with a surge coupler, you may get away with maneuvering the trailer slowly and gently on a level site without the brakes activating, but the majority of the time the brakes will come on. The coupler cannot differentiate between going forward or backward. To get around this problem, there are a couple of options depending on the brand of coupling you purchase. All couplers will have either or both options available.

The simplest method is a lock out pin which is manually inserted into the coupler to prevent the movable head from sliding back. There is a serious disadvantage to this method without even considering having to get in and out of the tow vehicle to insert the lock out pin. The problem is forgetting to remove the pin after the reversing procedure. The next time you take off down the highway with a full load, you have no brakes! This has caused many serious accidents and fatalities.

A safer and almost foolproof method is a built in reverse lock out electric solenoid, which is activated from the tow vehicle when the reversing lights come on (trailer needs to be appropriately wired) and will shut down any hydraulic fluid from traveling down the brake lines. This is the most efficient and safest reversing setup and is highly recommended.

Lock out solenoids can be retro fitted to most couplers and is well worth the price.

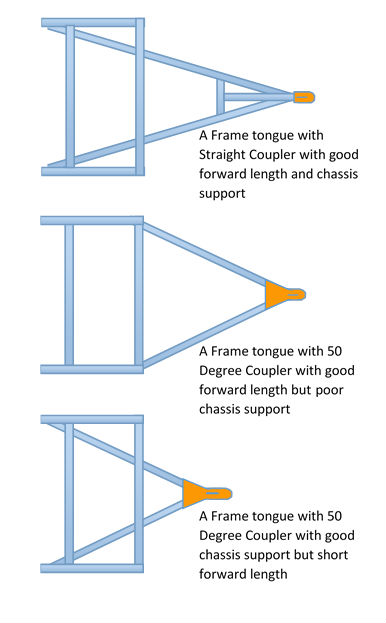

How your Coupler choice can affect your Trailer

The type of coupler you choose for your trailer can affect the overall strength of the trailer tongue and chassis. If your axle(s) is well set back from the center of the trailer you can get away with having a shorter tongue length (from the front of the chassis to the coupler). There is a rule of thumb to have the axle set at 60% of the chassis length, and this is fine for a lot of situations, especially where hinged rear ramps are used, but I prefer to have the axle set at 3" to 4" behind the center of the chassis and have a nice length of trailer tongue sticking out the front.

The reason for this preference, it that the longer tongue gives more stability to the trailer, when reversing you can see more of the trailer and gives the trailer more room to mount tool boxes, spare wheels, bicycle racks and the like. Having the axle set just slightly back from the center allows the trailer load to be more efficiently balanced without adding too much additional weight to the tongue.

Fitting a straight coupler to an A frame tongue, does take a bit more work inserting a straight steel section within the A frame, but if you are considering fitting hydraulic brakes to the trailer at a later stage, then this is an easy retro fit if the straight insert is fitted.

Ideally the tongue should finish at or near the front spring hanger to give the chassis additional strength. Terminating the tongue too close to the front of the trailer allows the chassis to flex and twist and could compromise its stability and trailer lifespan.

One of the drawbacks of an "A" frame coupler is the compromise you have to make regarding the length of the tongue forward of the chassis and the amount of support the tongue gives to the chassis. Depending on the width of the chassis, to ensure the tongue goes under the chassis sufficiently to give support, the forward tongue length is reduced. My personal preference is for straight couplers which can be mounted to the "A" frame tongue where the angle of the "A" frame can be adjusted to get good chassis support. See more on tongue design here - Tongue Design