Overslung or Underslung?

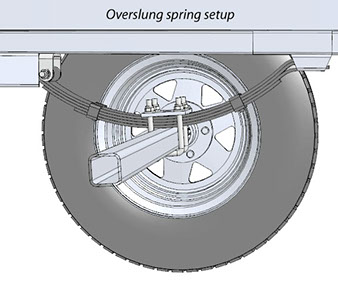

The axle position in relation to the spring needs to be considered before building. The options are “overslung”, where the spring is mounted over the axle, or “underslung” where the spring is mounted under the axle.

The axle position in relation to the spring needs to be considered before building. The options are “overslung”, where the spring is mounted over the axle, or “underslung” where the spring is mounted under the axle.

On a single axle trailer with standard eye/slipper springs, “overslung” is a common setup as the clearance between the top face of the spring and underside of the chassis is limited and the axle would bang against the chassis under load if mounted underslung.

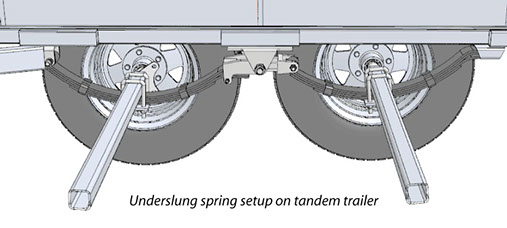

There is normally sufficient clearance to mount the axle underslung on a trailer using eye/eye style springs and on tandem trailers where an oscillating/rocker load sharing system is used to compensate for the additional depth of the rocker unit.

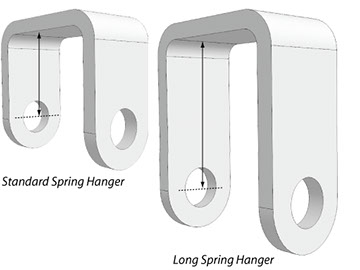

Note – if it is necessary to use an underslung axle on eye/slipper springs and clearance is an issue, source a spring hanger “U” bracket with a deeper “U” section.

Note – if it is necessary to use an underslung axle on eye/slipper springs and clearance is an issue, source a spring hanger “U” bracket with a deeper “U” section.

There is no advantage to either system in regards to trailer strength or ride, but does affect the height of the chassis/tongue above the road and depending on the load can aid or hinder trailer stability.

As with stepped and dropped axles, a lowered deck height (underslung) can be an advantage to trailer load stability especially if the load has a high center of gravity (top heavy) or where access to the trailer deck for loading/unloading requires a lower deck.

Too low a deck can be a hindrance and parts of the chassis can drag on the road particularly if traveling over undulating ground, going up or down driveways and over curbs.

Too low a deck can be a hindrance and parts of the chassis can drag on the road particularly if traveling over undulating ground, going up or down driveways and over curbs.

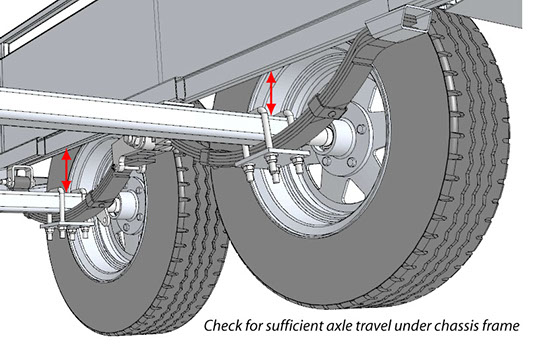

If you are going for an underslung setup, check there is sufficient clearance between the top of the axle and the underside of the chassis, and be aware that any change of axle height will alter the coupler height and the deck/bed angle.

If modifying an existing trailer axle setup, the coupler height will need to be adjusted to ensure a level deck when hooked up to the tow vehicle.

The difference in deck height between an overslung and underslung setup using straight beam axles is normally the depth of the axle and spring packer plus the full thickness of the spring.

Using a 2" x 2" SHS axle with a 3/8" spring packer and a 5 leaf spring with 1/4" thick leaves, the difference in deck height would be 2"+ 3/8" +(5 x 1 /4") = 3 5/8".

Axles need to be manufactured to both enhance the spindle in strength and stability as well as provide a factor of safety over and above the load rating of the axle as a whole. Axles take a huge amount of abuse from both the trailers loaded weight pressing down as well as all the knocks and bumps coming up from the road. Any weakness within the axle, can cause microscopic fatigue cracks leading to eventual failure of the axle.