3.6 X 2.0m Flatdeck Trailer

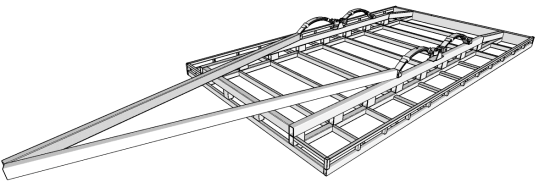

Drawbar

FITTING THE DRAWBAR

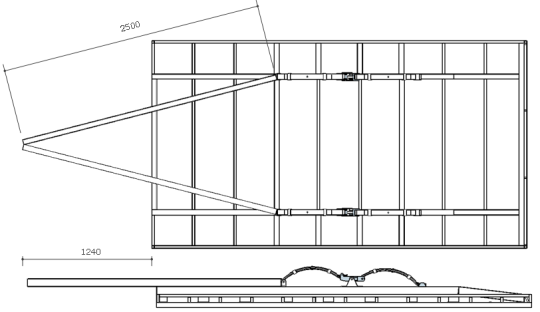

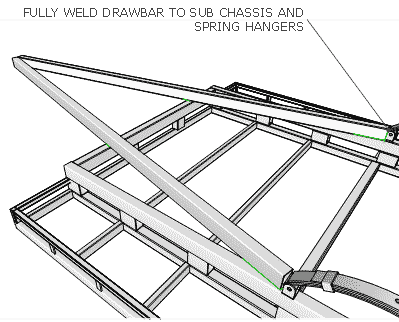

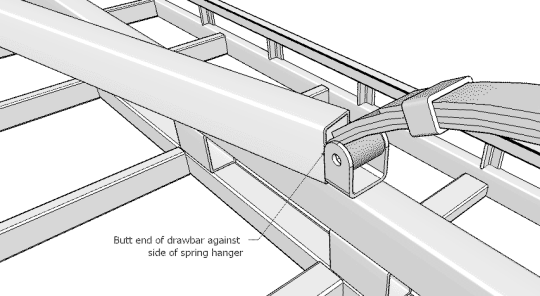

Lay the two drawbar sections down the centre of the trailer parallel with the chassis rails with the long edge vertical. Take one section and slide the inside end around till the inside edge is resting against the inside upright of the spring hanger and tack weld in position.

At this point it is a good idea to double check that the drawbar is central and to do this take a couple of measurements from the same point on the drawbar diagonally back to a point on the chassis in a couple of positions and check that both measurements from each side match.

If not you will need to recheck the position of the spring hangers and the lengths of the drawbar sections.

If needed reposition the hangers or grind the drawbar to suit.

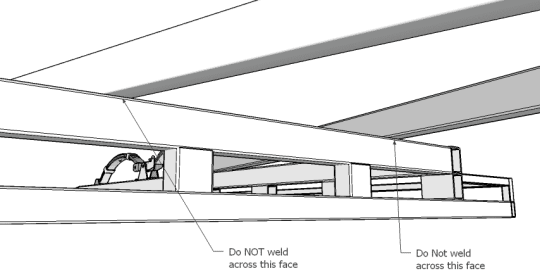

At this point you can weld up the drawbar in all the downhand and vertical positions. Do not under any circumstances weld across the horizontal faces on the drawbar where it intersects the front cross member as shown below. See here for more details - Drawbar Welding