BUILDING TRAILER AXLES

NOTE - Building your own axles should only be undertaken by a skilled and proficient welder equipped with a heavy duty, industrial strength welding machine. Good weld penetration with no porosity or undercut is required to ensure the strength and integrity of the axle is not compromised. If you have any doubts about your skills, leave axle building to the professionals, poorly built and poorly welded axles can cause accidents and kill people.

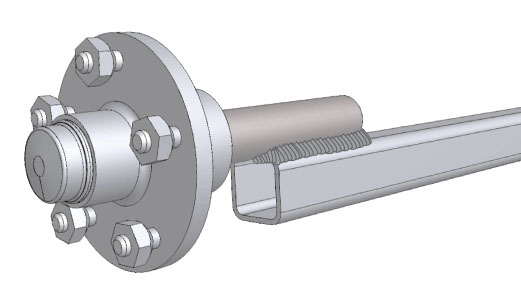

Trailer Axle Parts and Materials

Selecting the right kind of hub and spindle for your trailers gross loaded weight is relatively straight forward although care needs to be taken to get the best possible quality for all the components from the spindle steel type, and quality cast hubs, through to branded bearings, marine grade seals and quality wheels lugs and nuts. Most suppliers will have their own branded hubs and spindles and will have a designated load rating.

Hubs and spindles are subjected to the extremes of the road conditions, overloaded trailers, water, dust and everything else flung up from the road so getting the best quality hub /spindle set you can afford should give you a long and trouble free trailering experience.

Look for quality branded bearings to suit - Timken, SKF & NTN, NSK, Koyo, INA, & FAG are among the better manufacturers and are normally European or Japanese made. Stay away from bearings without a manufacturers stamp or markings.

The same goes for seals - preventing water and dust getting in, and keeping the grease from getting out of the hubs and bearings is a priority to prevent bearing failure. Double or triple lipped seals need to be fitted at a minimum.

Spindle steel varies from low grade mild steel to a higher grade medium tensile steel like AISI 1045 and come in both solid round & square. High tensile steels are not ideal for spindles as they do not have the flexibility to handle the stresses placed on a trailer. Along with your bearings, check the quality of the spindle steel and if the supplier can’t tell you what grade it is, go elsewhere.

Spindle back end diameters/width (round & square) for standard trailers range from 1 3/4" (3500 lb), up to 2 1/4" (5200 lb). Smaller and larger sizes are available.

If you are welding your own axles, finding a suitable axle tube or receptacle to contain the stub axles without compromising strength and accuracy can be tricky.

Axle Tube Material

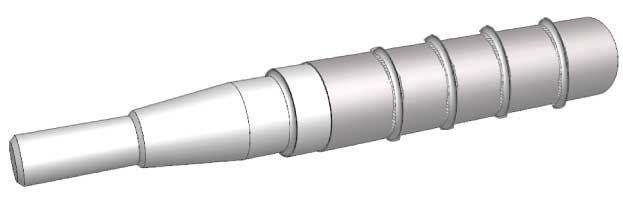

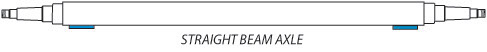

Straight Beam Axles

For 1 3/4" (1.75") round axles, you cannot go past a good piece of 1 1/2" Schedule 80 line pipe. The overall diameter is 1.90" with a wall thickness of around 0.2". The cut to length pipe will need to be sent to a machine shop to be internally bored out to suit the axle, but in doing so hugely reduces the time setting up the axles for true running.

1 3/4" heavy ERW pipe can also be used although there will be clearance around the stub that will need to be equalized to ensure the axle is central – see axle building methods detail below

Round stub axles are commonly welded into square hollow section (SHS) and 2" x 2" x 1/4" are suitable.

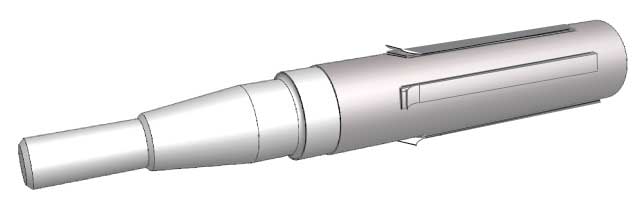

Finding a suitable axle material for 2 1/4" round and square axles is a bit more difficult and most people use this size stub axle in a stepped/overlay setup on top of 2 1/2" x 2 1/2" x 1/4" SHS or heavier.

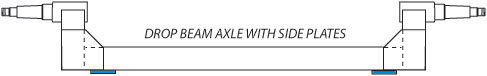

Overlay & Dropped Axles

For 3500 lb axles, the most common material for axle tube is 2" x 2" x 1/4" SHS (Square Hollow Section). For heavier duty axles, 2 1/2" x 2 1/2" x 1/4" or heavier is recommended and in some instances, 2" x 3" or larger RHS (Rectangular Hollow Section) sections can be used.

Dropped axles can be manufactured from heavy line/steam pipe but can be a time consuming exercise setting up and welding.

Axle Setup and Building

There are a couple of relatively easy methods of setting up spindles for accurate, true and straight running if you are not using machined pipe/tube.

Straight Beam Axles

The Shim Method is one of the easiest, and can be accomplished in almost any home workshop - This method uses shims fitted around the spindle to centralize it within the axle tube. Click here to go to the Shim Method Page.

The Weld and Machine Method is also a simple method which requires building up the spindle with weld before being machined to the right size for the axle tube. Click here to go to the Weld & Machine Page.

Overlay/Stepped Axles

For information on building overlay or stepped axles, quickly and simply, click here - Building Overlay/Stepped Axles

For information on measuring axles - Click here.